Bearings Parts

Repair service

Rolling element

We offer precision rolling elements which are manufactured in house under detailed control to achieve special curvature. This allows better rotation between bearing components, taking greater loads and a longer life.

Roller precision:P4

Partial parameter: P2Cylindrical rolling

∅10mm-200mm

L : 100mm~1700mm.

Tapered rolling

∅10mm-120mm

L: 100mm~1600mm.

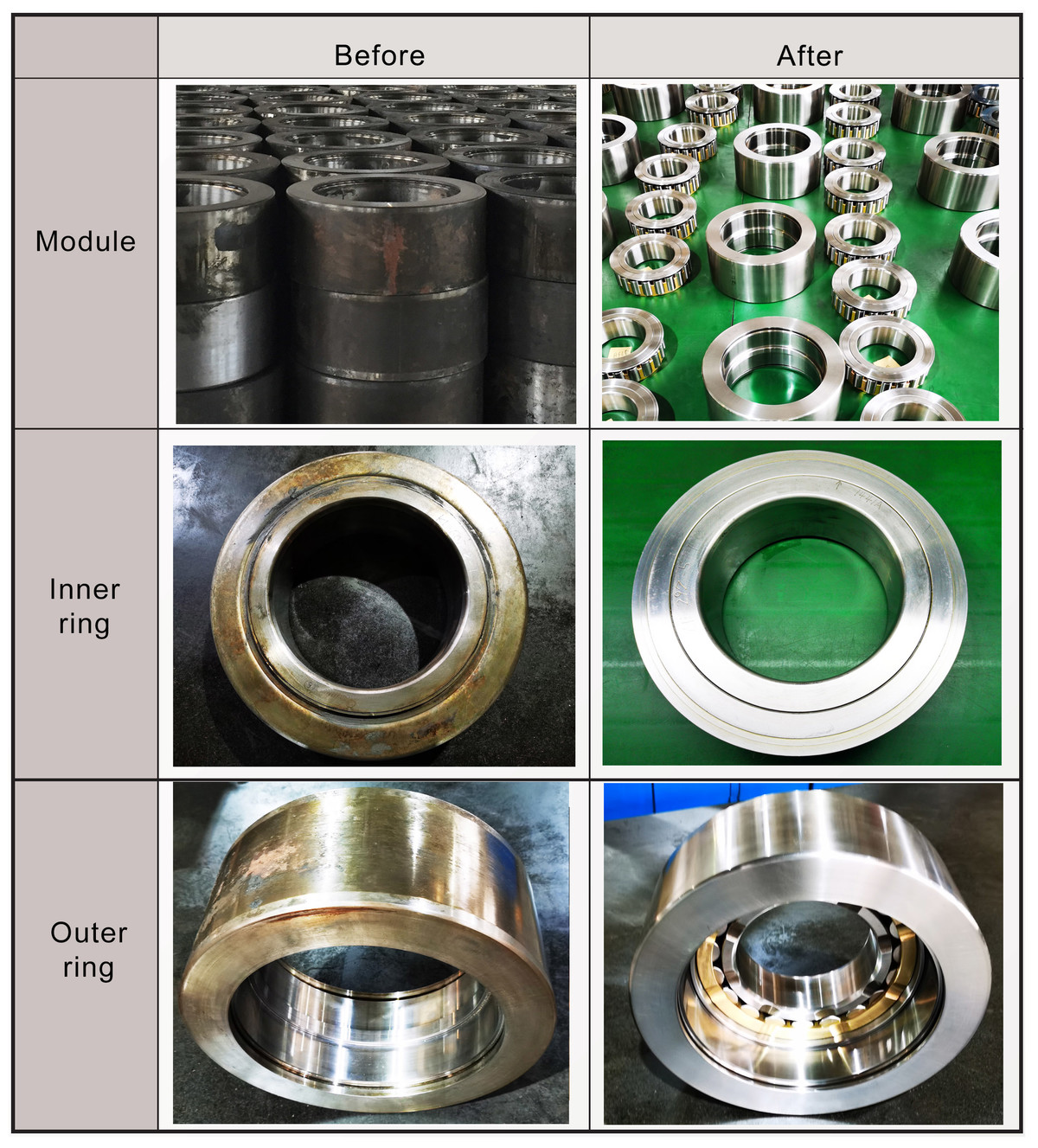

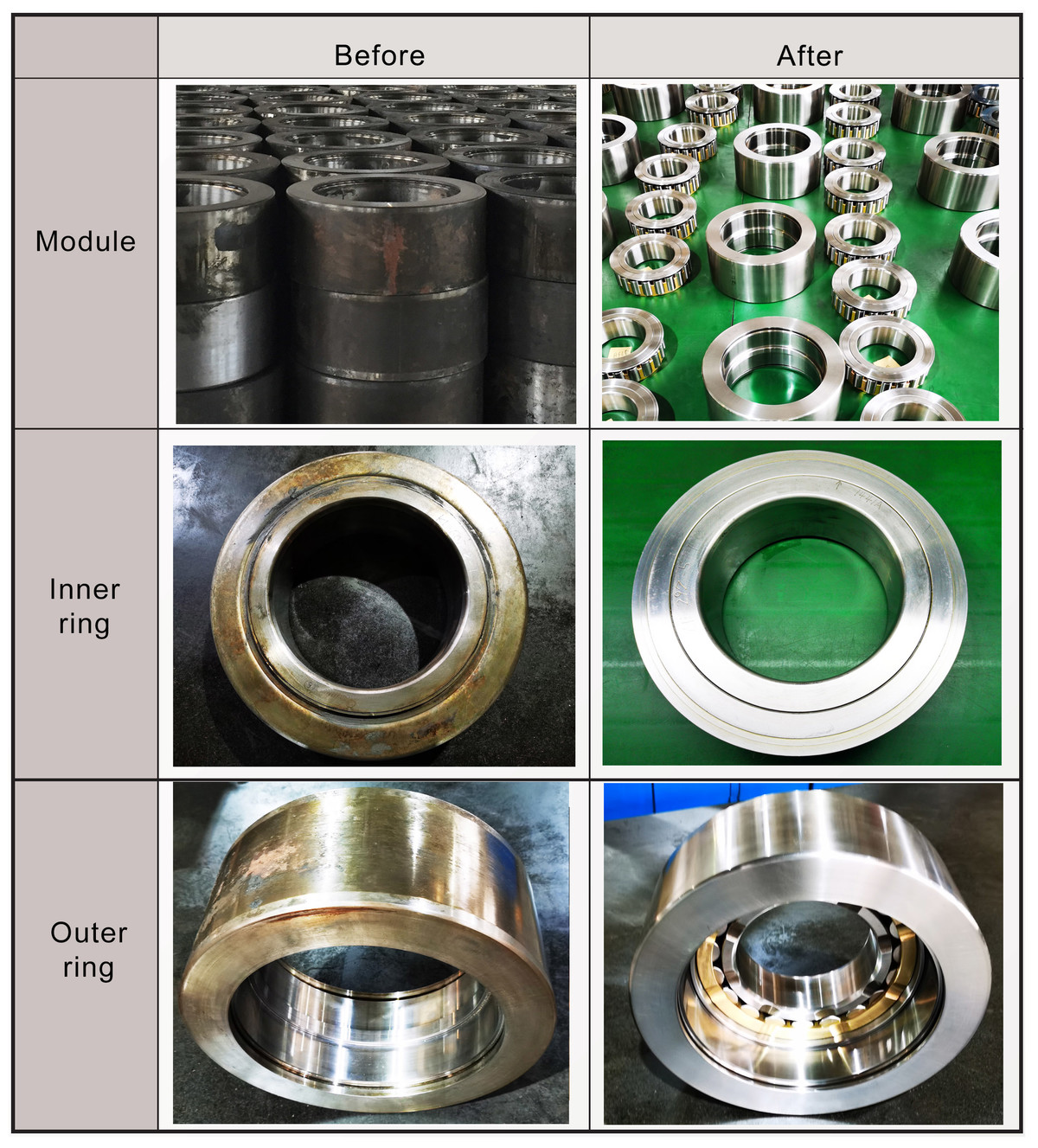

Repair Service

Reason For Repair

Periodical and timely inspection of large roller bearings and support bearings in production plants can effectively reduce and prevent occurrence of equipment failures and abnormal bearing damages. The maximum bearing life after repair is 80%* of the new bearing, but the repair cost does not exceed 50%* of the new bearing. ( * Reference value ).

Repair Process

1. Bearing disassembly and deep cleaning.

2. Outer ring measurement, condition assessment, grinding.

3. Inner ring measurement, condition assessment, grinding.

4. Rolling element measurement, group difference matching,

grinding.

5. Inspection of oil seals and seals.

6. Precision measurement, assembly and assembly of all parts.

7. Detect the wall thickness difference of each repaired bearing.

8. According to the measured data, the bearings are grouped

and numbered in sequence.

9. Re-cleaning, anti-rust treatment, packaging.

10. Certificate, delivery.

Head Office

No.369-7, Zuanshi Street,

Wafangdian, Dalian, China

E-mail:info@

Sales Center

No. 160, JinMa Road, Detai

Times Square, Dalian, China

Tel: +86-0411-8368-8899

Fax:+86-0411-8718-9077

E-mail:info@

Export Sales Agent

Shaanxi Trisun Economic Technology Import/Export Co., Ltd.

E-mail:ru-info@

Branch Office

Shanghai Office

Tel:137-7422-0497

...........137-7430-4849

Fax:021-33926960

Beijing Office

Tel: 137-0120-7962

Fax:010-59626542

Wuhan Office

Tel: 159-2769-0337

Fax:027-87862817

Zhanjiang Office

Tel: 133-7670-0451

Shaanxi Office

Tel:150-2998-1297

...........158-2991-5958

Fax:029-89861030

Shenyang Office

Tel: 133-0404-0501

Fax:024-31227098

Chengdu Office

Tel: 135-9400-6197

Fax:028-86799593

Guangzhou Office

Tel: 158-8990-0092

Fax:020-86552099

© 2022 Copyright

辽公网安备21028102000178号

辽公网安备21028102000178号